Recent advancements in thermal management technology have led to the development of gradient all-nanostructured aramid aerogel fibers (GAFs), which promise to revolutionize thermal insulation and structural performance. These innovative fibers, made through microfluidic spinning techniques, show remarkable properties including low thermal conductivity and high tensile strength, addressing the pressing need for effective thermal management systems.

Thermal management within buildings and vehicles is responsible for over one-third of global energy consumption, contributing significantly to carbon emissions. Therefore, researchers have focused on developing new insulation materials to mitigate heat loss, bolster energy efficiency, and diminish environmental impacts. Aerogels, known for their high porosity and unique thermal properties, have emerged as excellent candidates for such applications. Unlike traditional materials, aerogels can maintain flexibility, making them suitable for various uses including personal thermal management textiles.

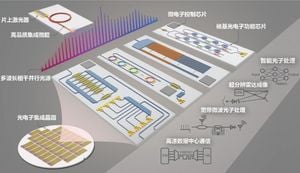

Traditionally, the production of aerogel fibers using methods like wet spinning often leads to dense outer layers, which diminish their insulating effectiveness. Recognizing this limitation, researchers have pioneered GAFs, engineered to have both sparse outer and dense inner structures, resulting from their unique microfluidic spinning process. This controlled production technique allows for the creation of fibers with average pore diameters of 150 nm on the outside and 600 nm on the inside, optimizing thermal insulation by enhancing interfacial resistance.

Through rigorous testing and simulation, GAFs achieved remarkable radial thermal conductivity values as low as 0.0228 W m−1 K−1, far below those attained by conventional wet-spun aerogel fibers. Interestingly, experiments showed significant enhancements when compared to existing aerogel products, with GAFs showcasing increased porosity (from 98% to 98.6%), reduced density (from 20.5 kg/m3 to 15.7 kg/m3), and enhanced tensile strength (from 10.9 MPa to 29.5 MPa).

This gradient nanostructure not only maximizes thermal insulation but also imparts significant mechanical advantages. GAFs demonstrated exceptional durability and resistance to stress, achieving fracture strains of 39.2%. The results are correlated with molecular dynamics simulations which indicated how gradients can substantially improve thermal performance by affecting heat transfer pathways.

Females give birth to multiple pups at once, and all demonstrate high survival rates thanks to the insulation capabilities of their mothers’ fur, which inspires the design of GAFs. Mimicking the natural insulation found within animal fur, GAFs effectively utilize nanostructures to manage heat, promising extensive applications in thermal protection for textiles, construction materials, and extreme conditions found in aerospace and firefighting tools. These fibers can be seamlessly integrated with existing products, explored within specialty textiles, or used independently for innovative thermal insulation technologies.

The potential for wide-scale production of GAFs is promising, as their microfluidic spinning method can easily be adapted for manufacturing on various scales. Researchers have illustrated the feasibility of producing these fibers economically, allowing for extensive applications beyond traditional uses. The spinning system enables flexibility not only in product design but also across diverse industries from personal textiles to infrastructure solutions.

To demonstrate effectiveness, GAF textiles, even as thin as 0.5 mm, yielded temperature differentials of 33.4 °C at low temperatures and 63 °C at high temperatures, showcasing their insulation capabilities. Increasing thickness to 1 mm improved these differentials significantly, underscoring the role of these materials across various practical applications.

Studies supporting the development of GAFs significantly enrich discussions surrounding advanced material engineering, proving beneficial not only for scientific enthusiasts but also for consumers seeking sustainable solutions. By bridging the gap between innovative design and practical necessity, this research reiterates the need for environmentally sound materials, championing improvements within the industry.

With GAFs marking notable advancements, the future of thermal insulation seems brighter. By addressing long-standing challenges within the aerogel market, GAFs pave the way for innovative insulation structures, highlighting the important interplay between material design and energy sustainability. This research establishes clear connections between the multiscale nanostructures and their practical applications, offering hope for new developments aimed at reducing our carbon footprint.

GAFs stand not only to change traditional concepts of insulation but to redefine efficiency and sustainability within various sectors overwhelmingly dependent on superior thermal barriers. The path forward reflects broader trends emphasizing the importance of material performance with ecological consciousness, creating opportunities for extensive exploration and application.