Researchers have conducted an experimental study on twisted spiral tubes, revealing significant advancements in heat transfer attributes compared to conventional smooth tubes. The study, focused on optimizing heat exchanger designs, showcases how varying the pitch and depth of twisted tubes can enhance thermal performance.

The experimental investigation tested three twisted spiral tubes with pitches measured at 3.9 mm, 5.2 mm, and 8.2 mm, respectively corresponding to pitch ratios of 0.278, 0.372, and 0.586. Additionally, variations in depth were also explored with values of 0.6, 0.95, and 1.15 mm corresponding to depth ratios of 0.043, 0.068, and 0.082. The Reynolds number during the experiment ranged from 5000 to 50,000 for the inner tube and from 1400 to 10,400 for the annular side.

The findings indicated a remarkable thermal performance of the twisted spiral tubes. For instance, the tube with a pitch ratio of 0.278 achieved a 38% enhancement in the Nusselt number compared to the smooth tube reference, alongside a 33.2% increase in friction factor. Similarly, the depth ratio of 0.082 resulted in a 44.9% improvement in the Nusselt number, while also increasing the friction factor by 36.4%. Overall, the study established new correlations that allow for predicting heat transfer and frictional characteristics of the twisted spiral tubes.

The double twisted spiral heat exchanger is noted to have extensive applications across industries, including oil refining and refrigeration systems, capitalizing on the enhanced thermal efficiency.

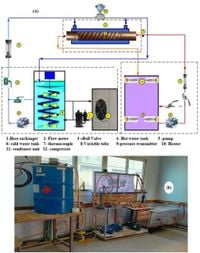

The design methodology consisted of experimental apparatus comprising a closed-loop system for both hot and cold water, where variables such as hot water temperature were precisely maintained during experiments. Results demonstrated that the counter-flow arrangements outperformed parallel flow configurations. For instance, under the same conditions, the Nusselt number in counter-flow increased by 16% compared to parallel flow regimes. This is indicative of advantages achieved through maximum temperature differences between the fluids.

The computational aspect of the research also focused on validating the experimental findings. Validation procedures involved comparing the experimental results with previously published data and established correlations, which confirmed the reliability and accuracy of the new findings.

Overall, this research highlights the benefits of using twisted spiral tubes in heat exchangers not only for improving thermal performance but also for efficient energy consumption in various industrial applications.