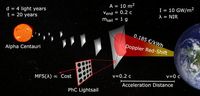

The Starshot Breakthrough Initiative aims to send gram-scale microchip probes to Alpha Centauri within 20 years, propelled by laser-driven lightsails at a fifth of light speed. This ambitious project has taken a significant leap forward, offering innovative insights into the development of scalable and cost-effective lightsail technology.

Currently, human-made objects like Voyager 1, which has been traveling through space since 1977, have only recently left our solar system, traveling just a fraction (0.5%) of the distance to Alpha Centauri. Traditional propulsion systems would see such missions take over 10,000 years, prompting the quest for new methods of space exploration.

In 2016, the Breakthrough Prize Foundation championed the Starshot Initiative, proposing the use of low-mass microchip satellites accelerated by laser-driven lightsails. By utilizing advances in nanotechnology, this mission aims to reach Alpha Centauri within 20 years, achieving speeds up to 20% of the speed of light.

Among the main challenges of the Starshot mission is developing an effective lightsail. A proposed design utilizes single-layer silicon nitride (SiN) photonic crystals, optimized through neural topology techniques. This approach reduces manufacturing and launch costs by about 9000-fold, with potential savings per lightsail reaching approximately 25 million euros. These advancements allow the production of a lightweight, high-performance lightsail that meets stringent project requirements.

Lightsails need to achieve sufficient reflectivity to endure the Doppler red-shift, which occurs as they accelerate. The ideal materials must also operate within the near-infrared (NIR) spectrum, making it feasible to mitigate thermal damage from high-power laser beams.

The initiative's researchers successfully fabricated a compact 60 × 60 mm2 reflector with over a billion nanoscale features, achieving a remarkable aspect ratio. By focusing on a pentagonal lattice design, they've discovered a capability to enhance both acceleration performance and cost-effectiveness, representing a significant breakthrough in the fabrication of high-aspect-ratio nanophotonic elements.

Furthermore, traditional manufacturing methods posed hurdles regarding speed and efficiency. In contrast, when employing optical lithography, the estimated writing time for a 10 m2 sail was dramatically reduced from 15 years to just one day. This shift allows for the rapid scaling of production processes, crucial for the multi-sail approach envisioned by the Starshot Initiative.

As lightsails accelerate in response to laser forces, the physics of propulsion depend heavily on minimizing weight while optimizing reflectivity. The study indicates that optimizing the photonic crystal designs can yield significant benefits not only in the lightsail's acceleration capabilities but also in the corresponding costs associated with launching them.

Notably, the research underscores the importance of navigating the challenges of both manufacturing costs and performance. Balancing these factors is central to the feasibility of achieving interstellar travel objectives within the proposed timelines.

The findings from this initiative herald new possibilities in the field of space exploration. If the Starshot Initiative's ambitious goals come to fruition, we may witness a transformative era in humanity’s quest to reach our nearest stellar neighbor. Initiatives like these not only explore the physical limits of our technological capabilities but also foster innovation across fields such as photonics, structural engineering, and materials science.

As researchers continue to optimize these designs, the interstellar exploration landscape appears to be on the brink of a significant evolution, paving the way for future missions that could redefine our relationship with space.