On September 3, 2025, a team of South Korean researchers announced a breakthrough that could reshape the future of medical implants and bioelectronics. Scientists from Kyung Hee University and Sungkyunkwan University revealed they had successfully developed a biocompatible, stretchable semiconductor that can be safely implanted into the human body, overcoming longstanding hurdles of immune rejection and mechanical incompatibility. The details of their innovation were published in the prestigious journal Nature Electronics on September 1, 2025, according to multiple Korean media outlets including 헬스코리아뉴스 and 뉴스1.

For decades, engineers and doctors have dreamed of electronic devices that could live inside the human body—monitoring health, delivering therapies, or even controlling prosthetics—without causing the immune system to attack or the device to break down. Until now, most implantable electronics have relied on rigid materials like silicon, which simply don’t move like skin or muscle. That mismatch often leads to inflammation, scarring, and eventual device failure. Even recent advances in flexible industrial electronics have struggled to meet the rigorous safety and compatibility standards required for long-term use inside living tissue.

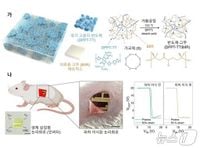

The new device, developed by the teams led by Professor Jin-Young Oh of Kyung Hee University and Professor Seok-Ho Bang of Sungkyunkwan University, changes the game. By blending medical-grade rubber with organic polymer semiconductor nanofibers using a process known as vulcanization, they created a material that is both stretchable and biocompatible. This combination allows the device to move and flex with the body, dramatically reducing the risk of tissue damage or immune response.

What’s the secret sauce? According to 헬스코리아뉴스, the researchers used a noble metal nanoalloy—specifically a dual silver-gold (Ag–Au) electrode—to ensure the device could operate stably in the harsh, salty environment of body fluids without corroding. The transistor itself features a two-layer structure of indium oxide and zinc oxide, with 50% indium substitution, which together enable robust performance even under significant stretching and in fluid-rich conditions.

To put their invention to the test, the team subjected the device to a battery of rigorous trials. In the lab, the transistor maintained stable operation under 50% tensile strain and in simulated body fluid at 37°C, the temperature of the human body. In animal studies, the device was implanted under the skin of mice for 30 days. According to the published results, there was no evidence of toxicity, inflammation, or excessive fibrous tissue formation—key indicators that the body was not rejecting the implant. The device’s performance also remained steady throughout the experiment.

Further, the team constructed basic logic circuits and active matrix arrays from the new semiconductor, demonstrating that it could serve as a foundational building block for more complex bioelectronic devices. These circuits, which are essential for digital computation and signal processing, operated reliably even after being stretched and exposed to body-like conditions.

But what about the device’s impact on living cells? The researchers didn’t stop at animal testing. In vitro experiments with human dermal fibroblasts—cells critical for wound healing and tissue structure—showed no negative effects on cell survival, movement, or gene expression. Likewise, tests involving macrophages, the immune system’s frontline defenders, revealed no abnormal inflammatory response.

Professor Jin-Young Oh summed up the significance of the team’s work, stating, “This research marks a decisive turning point for the commercialization of long-term implantable electronic devices by simultaneously securing the stretchability and biostability of semiconductor devices. It has great potential to evolve into the next-generation electronic device form factor, beyond the current diagnostic and therapeutic implantable electronics and even beyond the smartphone.” As reported by 헬스코리아뉴스, Oh also highlighted the potential for a new paradigm in electronics through the fusion of the human body and electronic devices—a vision that has long captured the imagination of scientists and science fiction writers alike.

Importantly, the new semiconductor meets the international biocompatibility and safety standards set by ISO10993, which is a crucial step for any medical device intended for human use. The use of medical-grade elastomers as the base material ensures not only flexibility but also the safety required for implantation. The device’s resistance to corrosion and stable operation in body fluids—thanks to its innovative Ag–Au electrode design—further boosts its suitability for use inside living organisms.

According to 뉴스1 and STV뉴스, the announcement was accompanied by images showing the device’s structure, the blending-vulcanization process, and the results of subcutaneous implantation in laboratory mice. The visual evidence reinforced the team’s claims of stability, compatibility, and mechanical resilience.

The implications of this research are broad and exciting. The ability to create logic circuits and active matrices from a biocompatible, stretchable semiconductor opens the door to a new generation of implantable medical devices. Imagine pacemakers, neural interfaces, or biosensors that can flex and stretch with the body, lasting longer and causing fewer complications. The technology could also pave the way for advanced prosthetics, smart drug delivery systems, or even direct brain-computer interfaces that are safer and more effective than anything currently available.

Of course, challenges remain. Scaling up production, ensuring long-term stability beyond the initial 30-day animal tests, and navigating the complex regulatory pathways for medical devices will all be hurdles to overcome. But with publication in Nature Electronics and a growing body of promising data, the research is already attracting attention from both the scientific community and the medical device industry.

For now, the work of Professors Oh and Bang and their teams represents a major leap forward. By solving the dual challenges of mechanical compatibility and immune safety, they have brought the vision of seamless, long-lasting electronic implants a big step closer to reality. It’s a development that could soon touch the lives of countless patients—and perhaps, one day, change the very definition of what it means to be human.