In a significant breakthrough for carbon capture technology, researchers have developed a gradient spiral-structured nickel/cerium oxide (Ni/CeO2) catalyst aimed at enhancing the efficiency of carbon dioxide (CO2) methanation. This innovative catalyst design not only excels in converting CO2 into methane—a vital process for reducing greenhouse gas emissions—but also improves energy transfer within reactors, thus overcoming the common challenges associated with heat management.

The study, led by a team of scientists and published in Scientific Reports, showcases the potential of this new catalyst configuration. Utilizing a triple-passed reactor system, the team examined the effects of different flow rates on CO2 conversion and methane selectivity, revealing a striking performance enhancement when applying a gradient coating technique.

The research highlights that at lower flow rates of 100 milliliters per minute, the triple-passed reactor achieved an impressive 98.5% CO2 conversion efficiency and a remarkable 99.9% selectivity for methane. In contrast, the single-passed reactor operated under similar conditions recorded 96.4% conversion with identical methane selectivity.

However, the most pronounced advantages emerged at higher flow rates. When the flow rate was escalated to 3000 ml/min, the triple-passed system demonstrated a CO2 conversion efficiency of 83.4% and a methane selectivity of 94.9%, a substantial uptick compared to the single-passed reactor's outputs of 64% and 87.4%, respectively.

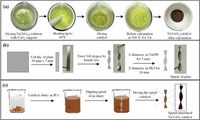

The catalyst's spiral structure plays a pivotal role in these enhancements. By adopting a gradient coating process, the research team ensured that thermal energy was effectively transferred from a heavily coated front catalyst section to a thinner-coated rear section. This strategic approach mitigated the formation of hotspots, a common issue that leads to catalyst deactivation.

"The gradient coating transferred heat energy from a thick-coated front catalyst to a thinner-coated back catalyst, reducing hotspots as well as improving mass transfer through swirling flow," explained the authors of the article. This innovative method addresses the dual challenges of ensuring efficient thermal management while optimizing the catalytic activity necessary for CO2 methanation.

The process used Ni as the primary catalyst due to its cost-effectiveness compared to noble metals, aligning with the need for scalable industrial solutions. Cerium oxide (CeO2) served as the catalyst support, facilitating better CO2 activation and enhancing catalytic stability through its unique oxygen storage properties.

Prior studies indicated that traditional nickel-based catalysts often faced challenges related to thermal management and catalyst longevity, especially in exothermic processes like methanation. The gradient-structured catalyst counters these limitations, making it a promising candidate for future developments in sustainable energy technologies.

The study was meticulous in its approach, employing a range of characterization techniques to analyze the catalysts, from X-ray diffraction to detailed chemical analysis through inductively coupled plasma-optical emission spectrometry. These analyses confirmed the successful integration of Ni and CeO2 and detailed the catalysts' structural attributes.

A major focus of the researchers was the operational efficacy between single and triple-passed reactors. Their findings indicated that while both configurations showed similarities in performance at lower flow rates, the superiority of the triple-passed reactor became evident under increased flow dynamics, facilitating enhanced gas interactions and improved catalytic outcomes.

The research not only delivers crucial insights into the optimization of CO2 methanation processes but also paves the way for future explorations into advanced reactor designs and catalyst configurations. With the pressing demands of climate change mitigation, innovations like these signify important steps toward practical applications in carbon neutrality.

As the study wraps up its findings, the authors stress the vital role of continued research in evolving catalyst technologies that could dramatically influence CO2 reduction strategies worldwide. With these advancements, the pathway to more efficient carbon management and energy production becomes increasingly feasible.