Innovative research has reshaped the way household sunflower seed hulling is approached, aiming to improve the efficiency of separating sunflower seed shells from kernels. A recent study published on March 17, 2025, introduces the coupling of Computational Fluid Dynamics (CFD) and the Discrete Element Method (DEM) as pivotal methodologies for refining this process.

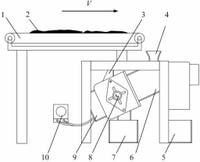

The primary function of the newly developed shell-kernel separation device is to utilize airflow to separate the lighter sunflower seed shells from the denser kernels, making the overall dehulling process more efficient. The significance of this research is underscored by the booming market for edible sunflower seeds, with estimates placing the size of this market at around 30 billion yuan as of 2022.

The study, conducted by researchers including R. Guan and J. Gu from Shihezi City, Xinjiang, identifies the optimal parameters necessary for effective separation. Through the introduction of pressure and velocity cloud images, the authors optimized the air channel structure, demonstrating how various factors influence the separation effectiveness.

To validate their approach, the researchers compared simulation results to physical experiments. The outcomes were promising, with statistical analyses—specifically T-tests—revealing P-values below 0.05 and relative errors consistently under 3.00%. Such validation confirms the reliability of the simulation methods used.

A key component of this research involved single-factor experimentation to assess factors such as air channel angle and wind speed, which are pivotal to improving separation rates. The systematic approach of using orthogonal designs enabled the team to determine the best combination of operating parameters, leading to findings where wind speed set at 6 m/s and air channel angle at 31° achieved remarkable shell-kernel separation rates of 89.91%, with only a 6.24% loss.

The experimental basis for this innovation begins with sunflower seeds sourced from the local “Shihezi Green Pearl Jiuding Market.” These seeds were processed to maintain specific moisture levels averaging 7%, which along with controlled atmospheric conditions provided optimal testing environments for evaluating the accuracy and efficiency of the shelling device.

The experimental design showcased how domain-specific optimizations could lead to significant enhancements over traditional methods. For example, the airflow dynamics were closely modeled using advanced simulation techniques, allowing researchers to pinpoint precisely how changes to the air channel design and mechanical parameters influence product yield and quality.

The analytical results highlighted the importance of airflow characteristics. By establishing the relationship between airspeed and separation efficiency, it became evident how even minor adjustments could drastically affect the separation performance. Experimentally observed separation rates significantly rose when the airflow parameters were aligned with theoretical predictions based on CFD-DEM models.

Following rigorous analyses of simulated outcomes, the research led to the formulation of comprehensive design criteria for household hulling devices. Clear guidelines emerged on optimal operational ranges, indicating the importance of adjusting the wind velocity and channel angle not just to maximize throughput, but also to minimize kernel loss.

Another compelling aspect of the study involved combining theoretical work with practical testing, presenting results from bench-scale experiments which closely matched simulation outputs, validating the efficacy of CFD-DEM methodology. The remarkable correlation between simulated and physical results fosters confidence in the design's real-world applicability.

To conclude, the research marks significant strides toward enhancing household sunflower seed shellers, creatively utilizing new technologies to address long-standing efficiency issues. With substantial validation and practical implementations on the horizon, this study sets the stage for transformative changes within the sunflower processing industry. Future studies will aim to explore additional avenues, such as integrating various airflow patterns and angle configurations to optimize results continually.