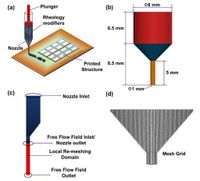

In recent research published on March 21, 2025, a team of scientists has shed light on the challenges surrounding the printability of inks used in direct ink writing (DIW)—a versatile 3D printing technique that deposits materials to create intricate structures.

Utilizing a numerical approach based on the finite element method (FEM), the researchers examined the printability of five distinct types of inks, including cement, thermoset polymer (epoxy), biopolymer (cellulose nanocrystals), and two hydrogel inks (alginate-based and metallic powder). Their findings emphasize the importance of specific rheological properties in determining an ink's suitability for DIW.

Printability refers to an ink’s ability to be effectively deposited and shaped in a manner that maintains structural integrity. The study identified critical factors such as shear thinning behavior, yield shear strength, and viscosity at suitable inlet pressures as key determinants of printability.

Importantly, the results highlighted that inks with improved printability demonstrated superior shear thinning behavior, which facilitates easier flow through the printing nozzle, along with better structural retention once deposited. Among the various inks tested, a composition of cellulose nanocrystals at 20 wt% emerged as the top contender, boasting the best printability scores.

DIW is an increasingly popular additive manufacturing technology due to its ability to create complex structures for applications across multiple fields including electronics, biomedical engineering, and structural engineering. As explored in this research, however, the printability of inks often relies heavily on their rheological properties—characteristics that typically require modification in their raw forms, often through the addition of rheology modifiers.

The study derived a printability grading parameter that enables a qualitative ranking of inks based on their rheological behavior, thereby categorizing them into high and low printability bands. This innovation is significant, as conventional approaches often relied solely on experimental methods to evaluate printability.

In practical terms, the research provides a new perspective on ink flow dynamics by utilizing numerical simulations to capture the behaviors of various inks under different conditions. The researchers aimed to analyze the effects of parameters such as pressure, shear stress, and viscosity, paving the way for future investigations into enhancing printability.

The findings also revealed distinct trends among the five types of inks. For example, the cement-based inks, when modified with nanoclay as a rheology modifier, showed a notable increase in printability due to improved flow characteristics. However, the study also noted that all inks exhibited non-Newtonian shear-thinning behavior, which is critical for effective printing.

Additionally, the researchers assessed how variations in ink concentration affected printability. The cellulose nanocrystals at 20 wt% allowed for a significantly lower inlet pressure compared to other inks, indicating a strong correlation between concentration and printability. This high-performance ink exhibited a viscosity of approximately 105 Pa.s, showcasing its robust characteristics necessary for successful DIW.

Conversely, inks with lower percentages or those not modified by appropriate rheological agents displayed higher inlet pressure requirements and less effective shape retention, thus categorizing them as lower-printability inks.

Overall, the results of this study reveal the intricate dynamics governing ink printability in DIW applications, providing valuable insights that could inform future developments in 3D printing technologies. As the field continues to evolve, optimizing the rheological properties of inks will be fundamental in expanding the capabilities of DIW, potentially leading to more efficient and complex manufacturing processes in various sectors.