In an era where industrial efficiency hinges on reliable machinery, understanding when gearboxes—critical components in numerous machines—will fail is more important than ever. Recent research by Zhang, Zeng, and Shi has uncovered a novel approach to predict the remaining useful life (RUL) of gearboxes using a time-varying kernel density estimation (KDE) method. This innovative technique could enhance industrial operations by preventing unexpected failures and optimizing maintenance schedules.

Gearboxes are essential in countless machines, translating rotational movement between components. However, their failure can lead to significant downtime and safety hazards. Predicting when a gearbox will fail is complex due to variable operating conditions and limited fault sample data available for analysis. Existing methods often struggle with inaccurate model structures or assumptions that hinder their effectiveness.

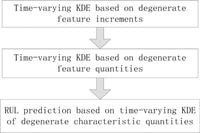

In their study published in Scientific Reports, the authors introduced a time-varying KDE model that accounts for the incremental distribution of gearbox degradation features. This model considers the crucial factor of time—specifically, the timing of sample data—by implementing an exponential weighted moving average method to accurately predict degradation trends.

The research highlights a significant advancement by leveraging real-time data collected from gearboxes during operation. Equipped with a sophisticated monitoring system, the scientists collected vibration and temperature data from gearboxes positioned 15 cm apart, operating under an output torque of 822.7 N m. By sampling data at a rate of 25.6 kHz over 60 seconds and using a 9-minute sampling interval, they were able to track changes in the gearbox's condition precisely.

The study's results were promising, demonstrating that the proposed time-varying KDE model provided superior RUL predictions compared to existing DGN and Ensemble models. The effectiveness of the method was evidenced by lower root mean square errors (RMSE) and mean absolute errors (MAE), crucial metrics for evaluating prediction accuracy.

One of the standout features of this research is the incorporation of adaptive window width in KDE, which adjusts the estimation window based on the density of the sample data. This adaptive approach led to enhancements in prediction accuracy, particularly when handling larger datasets.

The researchers also noted that as monitoring time progressed, the predictions converged more closely with actual values. For instance, at the 70-hour mark, the degradation characteristics predicted by the model differed significantly from the actual data, but the model became increasingly accurate as more data was collected throughout the operational period.

Another core aspect of the research involved the recursive updating of data as new samples were collected. This method reduces redundancy in calculations and optimizes the predictive process, streamlining the way gearbox performance is monitored over time.

In conclusion, the innovative time-varying KDE method proposed by Zhang and colleagues shows great potential for improving the predictive maintenance of gearboxes. By accounting for both time variations and adaptive density adjustments, this model not only enhances the precision of life predictions for mechanical systems but may also set a new standard for similar predictive technologies across various fields. The ongoing advancements in understanding gearbox dynamics will be critical as industries increasingly rely on automated systems for operational efficiency.