The study of Ferrium® M54®, a high cobalt-nickel ultra-high strength steel developed by QuesTek Innovations, reveals groundbreaking insights into its internal friction behaviors, providing a deeper understanding of the material’s transformative capabilities during heat treatment. By employing advanced techniques such as mechanical spectroscopy, X-ray diffraction (XRD), and transmission electron microscopy (TEM), researchers have identified critical relationships between the steel’s microstructure and its mechanical properties, highlighting the significance of heat treatment processes.

Initially, the investigation focuses on analyzing internal friction (IF) behaviors of cryogenically treated and tempered M54 steel specimens, through which the researchers identified three distinct IF peaks corresponding to specific thermal events during the heating and cooling processes. The peak P1 has been validated as a Snoek-Ke-Koester (SKK) relaxation peak, which is fundamentally linked to the behavior of interstitial carbon atoms in the martensitic matrix of the steel.

As the researchers conducted heating measurements, they noted that the peak P1 was sensitive to temperature changes and displayed a shift towards higher temperatures with increasing vibration frequency. This behavior illustrates its thermally activated relaxation mechanism, setting it apart from peaks P2 and P3, which are attributed to martensitic transformations throughout the thermal cycle.

Consequently, peak P2 is associated with reverse martensite transformation, characterized by a specific temperature point at approximately 750 °C, whereas P3 is linked to martensite transformation at around 350 °C. These results suggest that a strong crystallographic relationship exists between these peaks, indicating a complex interplay of structural changes during the thermal treatment of Ferrium® M54® steel.

Promising mechanical properties of Ferrium® M54® were highlighted, with ultimate tensile strength (UTS) reaching as high as 1965 MPa and a fracture toughness (K1C) value up to 110 MPa·m1/2, evident from the precision executed through optimized austenitizing and tempering procedures. These enhancements are crucial, positioning the steel as a promising contender for use in high-stress applications, particularly in aeronautical structures.

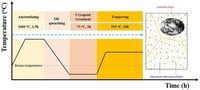

The treatment process starts at a temperature of 1060 °C where the specimens were held for 1.5 hours before rapid oil quenching. Following this, cryogenic treatment at temperatures of −73 °C for 2 hours was performed, facilitating deeper structural changes within the steel, including more robust phase transformation. Post cryogenic treatment, the specimens underwent tempering at 515 °C for 10 hours, which facilitated M2C carbide precipitation—known to contribute significantly to the ultra-high strength and hardness properties of the aged M54 steel.

During the study, X-ray diffraction techniques provided invaluable insights, revealing that only the (0 1 1), (0 0 2), and (1 1 2) crystal planes of martensite were observed, with no significant evidence of carbides or austenite due to their limited size and presence. This lack of observable carbides denotes the low levels of these compounds formed during the initial heat treatment, further reinforcing the role of internal friction measurements.

Moreover, researchers successfully determined critical transformation temperatures: Ac1 at 562 °C, Ac3 at 867 °C, and noted that the martensitic start transformation temperature (Ms) was approximately 393 °C while finishing at around 286 °C. By identifying these temperatures in conjunction with IF peak behavior, the research illustrates a comprehensive thermal cycle that effectively maps the material’s behavior under diverse environmental conditions.

By employing mechanical spectroscopy as a tool, the authors shed light on previously unknown behaviors of interstitial carbon atoms within the martensitic phase, demonstrating how heat treatment impacts the migration and precipitation of these atoms. Ultimately, the evidence collected in this study illustrates the significant connection between carbon migration, internal friction peaks, and the resulting structural formations within ultra-high strength steels during heat treatment.

The findings pave the way for future explorations in optimizing heat treatment processes not only for Ferrium® M54® but for other ultra-high strength steels as well, potentially leading to advancements in aeronautical and high-stress applications. Highlighting the unique role of internal friction as a nondestructive technique further establishes its importance in materials science, particularly in understanding phase transitions and microstructural evolutions during thermal cycling.