In a breakthrough study, researchers have successfully revealed the formation and plastic behavior of amorphous gallium oxide (a-Ga2O3) through large-scale atomistic simulations combined with machine-learning interatomic potentials. Unlike its crystalline counterparts, the amorphous state of gallium oxide has been relatively underexplored. This research not only marks a significant advancement in understanding amorphous materials but also opens pathways for new applications in technology.

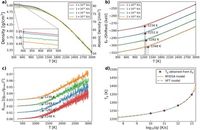

The study effectively demonstrates that the amorphization process of gallium oxide melt occurs at ultrahigh cooling rates, highlighting a distinctive glass transition temperature that varies between 1234 K and 1348 K depending on the cooling rate. These findings suggest that carefully controlling cooling rates is crucial for achieving specific structural properties in materials.

Importantly, structural analyses reveal notable similarities between a-Ga2O3 and amorphous alumina (a-Al2O3), especially in aspects like pair distribution function, coordination distribution, and bond angle distribution. These similarities were observed during simulations performed under tension, where a-Ga2O3 exhibited highly plastic behavior comparable to that of a-Al2O3. Such findings are particularly significant, as they challenge the traditional view that oxide glasses lack the capacity for plasticity.

Researchers noted that a-Ga2O3 has showcased a higher nucleation rate of localized plastic strain events (LPSEs) relative to a-Al2O3. This enhanced nucleation rate may contribute to increased resistance against shear band formation during deformation, a crucial factor for material stability under mechanical stress.

The simulations were executed at remarkably high temperatures, with liquid Ga2O3 achieving a density of 3.2 g/cm3 at 3000 K, while various cooling scenarios yielded densities ranging from 4.96 g/cm3 to 5.05 g/cm3 at room temperature. The findings indicate that while a-Ga2O3 holds a higher mass density due to heavier gallium atoms, its atomic arrangement is not as tightly packed as that of a-Al2O3, which may affect mechanical properties significantly.

With extensive characterizations taking place, the research group employed several methods to assess the material properties and conclusively validate the glass transition phenomenon in Ga2O3. One of the pivotal techniques involved computer simulations following a melt-quenching preparation process.

In conducting tensile tests on large amorphous structures, the Young's modulus for a-Ga2O3 was calculated, revealing a value of 113.74 GPa, which is consistent with expected trends for oxide glasses. The maximum stress observed during the tensile simulation was about 6.2 GPa, indicating substantial material strength, though slightly lower than that of a-Al2O3, which reached 6.6 GPa.

Analyzing the plastic behavior through the momentary local plastic strain, both a-Ga2O3 and a-Al2O3 performed similarly well under strain, leading to comparable amounts of highly plastic atoms involved in strain events. However, a nuanced investigation revealed distinctions, particularly in the sizes of plastic clusters, where a-Ga2O3 exhibited a greater number of smaller clusters, while a-Al2O3 showed fewer but larger clusters.

These insights into the mechanical properties of a-Ga2O3 not only contribute to a deeper understanding of material science but also elevate its potential applications in next-gen electronics, including photodetectors and other optical technologies, due to its unique functionalities.

Furthermore, the research highlights the applicability of machine-learning interatomic potentials in modeling amorphous materials, indicating a growing trend in computational methods to enhance material design and characterization. The results pave the way for exploring further the mechanical behavior and potential applications of Ga2O3 in various industrial domains.

As researchers focus on interfacing the fundamental understanding of atomic interactions with practical applications, the future of amorphous Ga2O3 and its integration into new technologies holds immense promise, revolutionizing the manner in which oxide glasses are utilized in the modern scientific landscape.