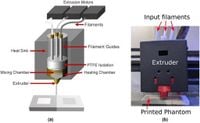

A new method has been developed for the direct three-dimensional (3-D) printing of complex optical phantoms that closely mimic human tissue properties. Researchers have utilized commercially available multi-color mixing extruders and polylactic acid (PLA) filaments to create tissue-mimicking optical characteristics, which they claim to be low-cost and widely accessible to various research institutions.

Diffuse optical imaging (DOI) technologies have gained traction due to their potential to non-invasively assess physiological details deep under the skin using near-infrared light. The authors have reported that the success of DOI relies heavily on precise measurements of light absorption and scattering properties in biological tissues. Previously, shortcomings existed with the manufacturing of solid optical phantoms that serve as standardized testing mediums for these imaging systems. Traditional phantom making processes often required significant labor and expertise, limiting their reproducibility across different laboratories.

The advantages of the newly developed method include the ability to produce complex phantom geometries that are tailored for specific research applications. The team created heterogeneous phantoms by mixing various gray, white, and translucent PLA filaments, which can simulate anatomical structures more accurately than traditional solid phantoms.

In their experiments, the researchers utilized a systematic approach to characterize the phantoms’ optical qualities, such as absorption and scattering coefficients, across multiple filament mixing ratios. They validated their hypothesis of a linear relationship between filament mixture and resulting optical properties, achieving an average error of 12% to 15% compared to model predictions.

“This method could revolutionize the standards for optical imaging in biological tissues, making it more feasible for many labs to create high-quality testing phantoms,” wrote the authors. “This opens a door for enhanced collaboration and standardization in diffuse optical imaging technologies.”

The practicality of this new 3-D printing method sets it apart from existing techniques, as it does not require complex pre-printing processes and minimizes the dependency on specialized equipment. It empowers researchers to fabricate phantoms that replicate the light-scattering properties of different tissues – critical for ensuring reliable results in various DOI techniques.

This approach aims to expand the effectiveness of applications such as functional brain imaging and cancer diagnosis by providing realistic phantoms that can aid in instrument calibration and performance validation.

To further illustrate the versatility of their methodology, the research team successfully printed anatomically detailed phantoms for quality assurance efforts in diffuse optics instruments. An example includes a segmented phantom based on the Digimouse atlas—one that accurately represents brain and lung tissues—and additional complex designs capable of testing advanced imaging systems.

The authors conclude that with further refinements and increased accessibility, this fabrication method could greatly benefit future research in optical imaging and contribute to the standardization necessary for advancing diffusion optical techniques.