In a groundbreaking study, researchers have explored the cutting-edge incorporation of titanium carbonitride (TiCN) and yttrium oxide (Y2O3) into aluminum nickel phosphorus bronze (Al-NPB) metal matrix composites (MMCs), aimed at enhancing the material properties essential for armored fighting vehicles (AFVs). This innovative approach to composite material science leverages the mechanical and ballistic strengths of these advanced nanofillers, potentially revolutionizing military defense technologies.

The significance of armored fighting vehicles cannot be overstated, as they are indispensable in modern military operations requiring agility and protection. AFVs are designed to foster a powerful balance between mobility and armor, optimizing troop safety and operational effectiveness in hostile environments. With continuous advancements in warfare tactics and technology, improving the composition of the materials used in these vehicles has become paramount.

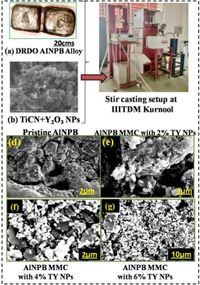

The research conducted by scientists at the Defence Research and Development Organization (DRDO) in India demonstrated the synthesis and application of TiCN and Y2O3 nanoparticles within the Al-NPB matrix through a meticulous stir-casting process. Specifically, the researchers performed mechanical tests on MMCs containing varying percentages of TiCN and Y2O3, observing that a 4 weight percent loading significantly enhanced mechanical strength compared to traditional materials.

To synthesize the TiCN + Y2O3 nanoparticles, pure yttrium oxide powders were mechanized with titanium carbonitride, creating an ultra-fine powder blend. This process involved a series of steps such as extensive milling and subsequent dispersion into the Al-NPB alloy. Rigorous characterization techniques, including X-ray diffraction (XRD) and scanning electron microscopy (SEM), confirmed the formation of nanocomposites and the quality of their microstructure.

This study underscored the promising results obtained during testing phases, revealing superior tensile strength, impact resistance, and corrosion durability. The ballistic testing emphasized the effectiveness of these composites, contributing vital data that highlights their applicability for AFVs.

As the researchers noted, “A 4 weight percent filler loading yielded optimal mechanical strength,” showcasing the delicate balance required to maximize performance. The team’s findings projected a clear path for further developments in lightweight, robust armor materials that cater to the stringent demands of modern military operations.

In conclusion, the newly developed Al-NPB MMCs reinforced with TiCN and Y2O3 not only represent a remarkable engineering accomplishment but also a critical advancement in military defense systems, promising enhanced protection for troops on the field. The integration of advanced composite materials will likely shift current standards for armored vehicles and inspire future innovations in material science.