Researchers at a prominent institution have developed a groundbreaking method to convert post-consumer polyethylene and polypropylene waste into valuable liquid fuels without producing methane, a major contributor to climate change. Utilizing an atomic ruthenium (Ru) doped zirconium dioxide (ZrO2) catalyst, the innovative approach yields liquid hydrocarbons with approximately 70% composition of jet fuel range branched hydrocarbons (C8-C16).

The study, published on March 21, 2025, in the Nature Communications, addresses critical environmental issues surrounding plastic waste through an efficient hydrocracking process. Traditional methods often generate low-value methane as a byproduct, diminishing the economic viability of such recycling efforts. However, this new technique manages to sidestep that problem through the catalytic properties of the Ru-ZrO2 system.

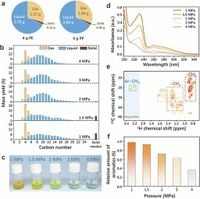

In a typical hydrocracking setup, the Ru1-ZrO2 catalyst operates effectively at 250 °C under 3 MPa of hydrogen, achieving over 98% conversion of polyolefins. The liquid yield amounts to 85 mL from 100 grams of processed plastics. Impressively, the gaseous byproduct generated is primarily liquefied petroleum gas (C3-C6) with significantly reduced levels of methane and ethane.

The innovation hinges on the creation of a Brønsted acid site from the interaction of the Ru dopant with the oxide's lattice oxygen. This newly active site is essential for selectively cleaving internal C−C bonds in polyolefins, which leads to a higher yield of desired hydrocarbons. As the study explains, the successful modulation of the catalyst marks a significant shift in how we approach plastic waste recycling.

"This method is not only efficient but also provides a sustainable pathway to reduce plastic pollution while conserving valuable fossil resources," said one of the authors. The implications of this work reach far beyond the lab; they underline the feasibility of integrating sustainable processes into the current industrial framework.

In practical applications, the catalyst has shown robust performance with no observable decline in liquid yield even after six cycles of operation. This suggests its potential for scaling up and commercial use, particularly as global demands for sustainable aviation fuels increase rapidly, projected at a compounded annual growth rate of 45%.

The demand for better recycling techniques is urgent. Currently, polyolefins contribute significantly to environmental pollution due to their resistance to degradation. By transforming these waste materials into high-value fuels, this new research holds promise for a more circular economy. The findings urge policymakers and industry leaders alike to reconsider existing practices in plastic waste management and seek innovative solutions that benefit not only the economy but also the environment.

As this research lays the groundwork for future advancements, it offers a glimpse into a sustainable world where waste is not simply discarded but instead reimagined as a valuable resource.