A newly developed high-speed inspection method offers a promising solution for ensuring the quality of cigarette filter rods in production, achieving an impressive rate of 4,200 inspections per minute.

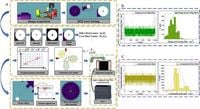

Utilizing advanced machine vision and an ellipse fitting algorithm, the new technique monitors the alignment of the mandrels in filter rods, a critical factor in ensuring product consistency and safety. As production speeds increase in modern manufacturing, traditional quality control measures struggle to keep pace, often leading to delays and undetected defects that can affect consumer safety.

The growing demands for rapid and precise inspection methods in various manufacturing sectors run parallel to the urgent need to enhance product quality. Cigarette filter rods serve a crucial role in trapping harmful particles in smoke, thus improving the smoking experience while attempting to reduce the negative health impacts of smoking. In line with this, filter rod manufacturers are increasingly implementing automation technologies to streamline production processes and enhance quality assurance.

The research conducted by Zhou, Wei, Yang, and their colleagues aims to tackle the limitations of existing quality control methods under high-speed production conditions. Their approach integrates an ellipse fitting algorithm to accurately ascertain the positions of filter rods and their internal cores. By measuring the mandrel deviation through Euclidean distance calculations, the system determines product qualification in real-time.

Experimental results have demonstrated the system's capability of detecting defects with an outstanding accuracy of over 95%, making it a valuable addition to the filter rod production industry.

Such advancements in visual inspection systems not only signify a leap in operational efficiency but also pave the way for improved consumer safety through enhanced quality control. As companies introduce designs that allow for seamless integration into existing production lines, this solution represents a significant stride toward innovative automation processes.

Each filter rod in the inspection process is evaluated based on its centering around the mandrel. If the deviation measured exceeds a predetermined threshold, the product is considered unqualified. The precise algorithms leveraged in this method ensure that operators can swiftly identify and rectify quality issues before products reach the market.

Conventional inspection techniques often involve manual processes, which are time-consuming and prone to human error. The introduction of automated inspection through machine vision combines speed with accuracy, ultimately enhancing production efficiency. Zhou and colleagues opted for a methodology that balances both technological advancement and practical application, optimizing their inspection setup for real-world industrial conditions.

The investigation further illustrates the complexity of developing robust quality inspection systems that operate effectively in challenging environments. With integrating various lighting methods, particularly high-power LED illumination, they overcame obstacles presented by dust and static interference common in production settings.

As the study notes, ``image preprocessing techniques play a vital role in elevating the accuracy of inspection results.'' Filter rods, made from intricate raw materials, necessitate careful quality checks to ensure their integrity throughout their lifecycle.

Going forward, the researchers suggest exploring combined approaches that integrate machine learning techniques with traditional image processing methods. Such hybrids could provide even greater precision in detecting subtle defects that may be categorized as false negatives in existing systems.

In conclusion, the presented method stands to revolutionize quality assurance in the filter rod manufacturing landscape. The continuous evolution in automation and machine vision technologies will drive improvements in product quality while maintaining necessary speed, ultimately ensuring that consumer health is prioritized.