A recent study published in Scientific Reports emphasizes the importance of precise measurements in thermoelectric materials, utilizing time-domain impedance spectroscopy (TDIS) to quantify key properties such as resistivity, dimensionless figure of merit, thermal conductivity, and Seebeck coefficient. This innovative approach allows for accurate determinations at room temperature, enhancing the potential of such materials in energy recovery applications.

Thermoelectric materials are recognized for their capabilities in harvesting waste heat and converting it into usable electrical energy. The efficiency and performance of these materials hinge on a dimensionless figure of merit, denoted as zT, which combines several thermoelectric properties. Specifically, zT is defined by the Seebeck coefficient, resistivity, and thermal conductivity of the material. Understanding these parameters is critical for the development of efficient thermoelectric applications.

Conducted by researchers from multiple institutions, the study involved rigorous testing of a bismuth-telluride (BiTe) thermoelectric module, known as the KSML007F, which is a Π-shaped design containing fourteen thermoelectric elements. Key findings from the research indicate that, under standard testing conditions set at 300 K, the resistivity was calculated to be 10.19 μΩm, with a zT value determined to be 0.8645 ± 0.0003. Additionally, thermal conductivity was measured at 1.259 ± 0.003 W/mK, and the Seebeck coefficient was found to be 192.3 ± 0.4 μV/K.

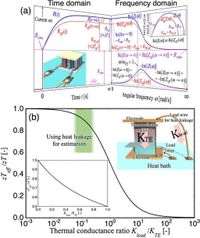

One critical aspect of the study was the evaluation of heat leakage through lead wires that connect the thermoelectric module. The researchers discovered that for precise measurements of thermoelectric parameters using TDIS, a thermal conductance ratio of Klead/KTE greater than 0.1 is essential. This insight underscores the significance of thermal management in the experimental setup and has implications for the design of future thermoelectric modules.

The methodology for determining these parameters involved a sophisticated combination of time-domain and impedance measurements. The researchers accounted for varying conditions that could impact the thermal conductance ratio and systematically assessed the effects of heat leakage on the accuracy of their measurements. The study showed how variations in the Klead/KTE ratio could lead to significant differences in the estimation of the zT value.

Furthermore, the use of time-domain impedance spectroscopy allowed for the direct measurement of the transient response of the thermoelectric module without requiring multiple sample shapes, which traditionally complicate thermoelectric property evaluation. This method is heralded for its potential to streamline the assessment of thermoelectric materials, particularly in scenarios where heat management is crucial.

The findings have broader implications for the field of thermoelectrics and future energy generation technologies. As nations and industries seek to reduce waste and enhance energy efficiency, optimizing the performance of thermoelectric materials could lead to significant advancements. The successful demonstration of TDIS in this study showcases its utility in material science and engineering applications.

Through careful experimentation, the researchers concluded that maintaining a rigid standard for the thermal conductance ratio is necessary to achieve reliable measurements. Establishing such criteria is expected to drive further developments in thermoelectric technology aimed at more effective energy conversion and utilization.

The research is a promising step towards improving the reliability of thermoelectric measurements, thus paving the way for enhanced applications across various industries. As interest in sustainable energy solutions continues to grow, innovations like these stand to play an indispensable role in energy recovery and conversion technologies.