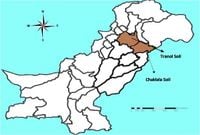

A comprehensive study published in Scientific Reports evaluates the use of coal waste and silica fume to enhance the mechanical properties of low-plasticity soils, commonly found in construction sites across Pakistan. Researchers from Qassim University investigated how these materials could serve as effective stabilizers for soils from the Tarnol and Chaklala regions, which traditionally experience inadequate strength and stability.

The study presents a significant development in geotechnical engineering by demonstrating that silica fume can increase the liquid limit (LL) of Tarnol soil by 36% while reducing its plasticity index (PI). In contrast, coal waste proved even more effective for Chaklala soil, enhancing its LL by 48% and reducing the PI—the results of which could lead to more resilient infrastructure projects. The unconfined compressive strength (UCS) of both soil types showed notable improvements. Tarnol soil treated with 12% silica fume exhibited a 77% increase in UCS after 28 days of curing, while Chaklala soil treated with 12% coal waste experienced an 83% rise in UCS—highlighting the potential of these materials as sustainable alternatives to conventional stabilizers.

Soil stabilization processes are crucial for the reliability of foundation materials in various civil engineering projects, including roads, bridges, and buildings. By optimizing the characteristics of low-plasticity soils through the incorporation of industrial by-products, this research contributes to environmentally friendly construction practices while addressing pressing engineering challenges.

Both coal waste and silica fume reduced the maximum dry density (MDD) while increasing the optimum moisture content (OMC) of the treated soils. For instance, the MDD of Tarnol soil was reduced to 24.568 kN/m³ with a corresponding OMC of 11.85% following the addition of silica fume. Similarly, Chaklala soil attained an MDD of 18.41 kN/m³ at an OMC of 13.53% with coal waste. This modification in soil properties illustrates that the use of specified proportions (3–12%) of these stabilizers could effectively enhance the geotechnical performance of low-plasticity soils.

The findings underscore the viability of using waste materials like coal and silica fume in soil stabilization. They open the door to cheaper, more sustainable methods of enhancing soil performance, which not only benefit construction projects but also contribute to environmental sustainability by repurposing industrial by-products. Both silica fume and coal waste, when properly managed, can reduce erosion, bolster soil strength, and afford a more cost-effective option than traditional stabilizers.

The study highlights the innovative ways in which engineering practices can adapt to use by-products from the coal industry, which traditionally raises environmental concerns due to heavy metal content. Despite the risks associated with coal waste, the research indicates that, with proper management, it can enhance soil stability without compromising environmental safety. This dual benefit makes it a compelling candidate for soil stabilization in areas susceptible to the challenges of low-plasticity soils.

Conclusively, as the understanding of soil stabilization evolves, the integration of waste materials like silica fume and coal represents a critical step toward more sustainable construction methodologies. Future research may yield further insights into optimizing these stabilizers to enhance soil properties, minimize environmental impact, and extend their applications in geotechnical engineering.