As the manufacturing landscape evolves with technology, metal additive manufacturing (AM) is taking center stage, particularly in sectors like aerospace and medical devices. This innovative approach, which builds complex items layer by layer through techniques like laser powder bed fusion (LPBF), has extraordinary potential to revolutionize production. However, issues such as low surface quality and internal imperfections, particularly porosity and cracks, have hindered its wider adoption. Addressing these challenges is crucial for unlocking the full promise of metal AM.

A recent study, published on March 22, 2025, explores a novel method that could improve the reliability of AM processes: in-situ temperature monitoring using eddy current (EC) measurements. This method offers a fresh perspective on assessing the temperature of the material being processed, a key factor in determining product quality and structural integrity.

The research team devised a thermally-coupled electromagnetic simulation model to understand the internal temperature distribution during AM. The simulation showed that the temperature evolves dynamically as the material undergoes both heating and cooling from the intense laser energy used in the LPBF process. The ability to monitor the transient temperature history is essential, as it directly influences the thermal stress distribution and residual stresses in the components being manufactured.

“The EC response can dynamically reflect the temperature of the AM material during both the heating and cooling processes,” wrote the authors of the article. This potential allows manufacturers to optimize laser parameters in real time, resulting in improved product quality and reduced production defects.

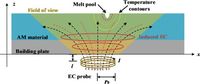

In their preliminary experiments, the researchers validated their simulation model using a soldering iron tip to heat a metal plate, achieving real-time temperature monitoring within a range of 420 to 700 K. This technique uses an EC probe placed beneath the build plate, avoiding the complications associated with integrating monitoring devices directly into the machine, which can disrupt the additive manufacturing process.

Throughout their experiment, the researchers recorded signals from the EC probe as it detected changes in magnetic flux density in the x, y, and z directions. These signals reflect changes in temperature and, consequently, material properties as the laser interacts with the metal powder.

Using a single-turn EC probe with a diameter of 6 mm, positioned at a lift-off of just 0.1 mm from the build plate, provided crucial insight into the effectiveness of this technique for real-time monitoring. As the researchers applied various levels of laser power ranging from 300 W to 500 W, they noticed a clear correlation—higher laser power produced stronger signals.

The consequences of this research are vast. “The method’s ability to directly capture and represent variations in parameters underscores its applicability in enhancing control and optimization processes within the system,” stated the authors of the article.

Moreover, the improved temperature monitoring could expedite the feedback loop in additive manufacturing, allowing for adjustments during the building process rather than post-production evaluations. Such advancements are expected to significantly enhance the reliability of AM products, particularly in high-stakes industries such as medical implants and aerospace components where precision is paramount.

As the experiments progressed, the findings indicated that the system could also effectively monitor the cooling process of AM materials post-laser activity. By extending observations to a duration of 8 seconds after the cessation of laser activity, the EC response continued to show valuable insights into temperature decay, further confirming the method’s practical potential.

The researchers aim to refine this approach and test its capabilities on more complex builds and geometries. Ultimately, this study presents a promising avenue for integrating advanced monitoring capabilities within metal additive manufacturing, allowing it to fully realize its potential in transforming manufacturing capabilities.