The rapid expansion of coal seam mining in the western mining area of China has posed significant challenges to both the structural integrity of the earth's surface and the safety of mining operations. As reported in a recent study on the 52,307 large mining height working face in the Daliuta Coal Mine, researchers found distinctive patterns of overburden rock deformation and surface cracking attributed to unique geological characteristics.

The study, released in Scientific Reports, highlights that the typical mining conditions, characterized by shallow burial depth, thin bedrock, and thick loose layers, have resulted in notable differences in the instability of the mine's structures compared to previous findings. This research plays a pivotal role in informing future mining practices and strategies for pressure control in shallow coal seams, particularly as demand for coal extraction continues to rise.

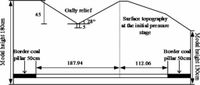

The investigation utilized advanced similar simulation and numerical modeling techniques to analyze how strata pressure and surface cracks develop as mining progresses. Researchers identified that when a key layer, situated merely four meters above the coal seam, undergoes breaking during the mining process, it creates significant challenges. As the key layer breaks, it falls into a collapse zone, leading to the formation of unstable structures, which in turn affects both the movement of overlying rock layers and the emergence of surface cracks.

Key findings from the study reveal the cyclical nature of surface cracking, with initial cracks appearing approximately 35 meters behind the advancing working face. As mining operations proceeded, by the time the face reached 270 meters, multiple new cracks had developed, largely influenced by the subsidence of the mined layers. Each stage of mining triggered specific responses in the overburden, with temporal lags observed in the appearance of ground fissures related to the dynamics of mining pressure.

Throughout the process, the breaking and migration of the key layer significantly influenced the movement of the overburden rock as a whole. This led to the conclusion that the overburden behaves as a large mass, which can generate tensile stress that manifests as surface cracks. The findings underscore the risk of ground fissures, raising concerns for the engineering controls necessary to ensure safe mining procedures.

The research team, led by Hui Cunhan and Lili Shi, incorporates insights from multiple collaborators, emphasizing the collaborative nature of understanding geological movements. As advancements in mining technology continue, such integrative studies are crucial for adapting mining methods to manage the complex interactions between mining activities and geological conditions.

In summary, the study not only highlights the intricate mechanisms behind overburden movement and surface deformation but also calls for further investigation into sustainable mining practices that can mitigate the adverse effects of coal seam mining. By understanding these dynamics, policymakers and mining engineers can develop better strategies to balance resource extraction with environmental safety and structural integrity.