Researchers at MAX IV Laboratory in Sweden and DESY in Germany have recently made a significant breakthrough in the field of X-ray imaging, successfully demonstrating a technique that combines multi-beam and multi-slice ptychography. This innovative method enables high-resolution imaging of thick samples, a longstanding challenge in microscopy.

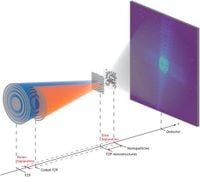

The recent study illustrates the effectiveness of this technique in overcoming limitations faced by previous imaging methodologies. Traditional X-ray imaging approaches often struggle to provide detailed information about the internal structures of large, thick samples due to issues with light penetration and scattering. However, the new multi-beam multi-slice X-ray ptychography can effectively manage the thickness of samples, allowing researchers to obtain precise, high-resolution images in a non-destructive manner.

At the heart of this advancement is the ability to scan multiple layers of a sample simultaneously. By utilizing various separations between layers, the researchers managed to resolve and reconstruct clear images of structures within different depth planes of their samples. This next-generation technique opens doors for applications across various scientific domains where detailed morphological and chemical analysis is required.

Specifically, the experiments were conducted at two cutting-edge facilities: the NanoMAX beamline in Lund, Sweden, and the P06 beamline at DESY in Hamburg, Germany. During these experiments, samples comprised of Si3N4 membranes embedded with gold nanostructures were analyzed. One membrane featured gold nanobricks, while the other held 200 nm gold nanoparticles, all positioned at varying depths to facilitate multi-slice imaging capabilities.

The innovative combination of multi-beam and multi-slice techniques effectively addresses previous constraints on spatial resolution that arise when imaging thick samples. As highlighted in the study, the newly established framework allows researchers to resolve images at depths comparable to their width, providing a deeper understanding of the investigated materials.

In their findings, the researchers achieved a resolution in the range of 2 to 3 pixels for all slices, confirming the potential for even thinner slice separations—potentially down to around 80 micrometers—opening up new avenues for future investigations. The power of combining these two advanced imaging techniques marks a significant leap in capabilities for non-destructive imaging and sample characterization.

Notably, this research culminates from rigorous experiments and considerable refinement of scanning methodologies. Each measurement was carried out using both single and multi-beam scanning approaches, with direct comparisons revealing that the multi-beam setup successfully produced images of equal or superior resolution to traditional single-beam methods.

As the adoption of multi-beam ptychography becomes more widespread, the implications for research will be vast. Enhanced imaging techniques could facilitate groundbreaking discoveries in material science, biology, and nanotechnology, allowing deeper and more intricate studies of complex systems without damaging the samples.

Further expanding the scope of this research, the authors have developed software routines to facilitate the handling of multi-beam multi-slice datasets, which will be made available for future experiments across similar ptychographic frameworks. This simplification means that advancements in multi-beam imaging can be undertaken without extensive modifications to existing experimental setups.

With the support of institutions like the Swedish Research Council and DESY, this pioneering work not only showcases a promising future for imaging techniques but also highlights collaboration among leading facilities dedicated to advancing scientific research.

As researchers continue to innovate in the realm of imaging and characterization, the integration of multi-beam and multi-slice ptychography represents a crucial step forward in the ongoing effort to understand and manipulate materials on the nanoscale.