Bismuth prices in Europe have surged to an all-time high as China’s recent export controls squeeze supplies of the mineral used in various industries, including atomic research, cosmetics, and pharmaceuticals. According to traders and experts, the price of bismuth skyrocketed to $40 per pound on the European spot market as of March 19, 2025, a staggering rise from just $6 per pound in late January. This increase represents more than a six-fold jump in recent months.

In the United States, the situation is even more pronounced, with bismuth prices hitting $55 per pound compared to $6.5 to $7 before China implemented its export restrictions. The surge is attributed to supply shortages resulting from China’s planned export controls on five critical metals: tungsten, tellurium, molybdenum, bismuth, and indium, announced in February 2025 in response to tariffs imposed by former President Donald Trump on imports from the world’s top bismuth producer.

The impact of these export controls is particularly worrying for traders who note, “at the moment there are no supply sources to fully replace Chinese material.” The analysts from CRU Group, a business intelligence company, noted that much of the supply tightening is policy-driven and “it can ease very quickly.” However, the complete cessation of Chinese bismuth exports would necessitate new capacity outside of China.

Notably, the U.S. Geological Survey (USGS) highlighted China’s dominance in the bismuth market, stating that last year, it produced approximately 13,000 metric tons of mined bismuth, accounting for over 80% of the global total. The remaining production comes from Japan, South Korea, and Laos, but not at a scale large enough to offset China's significant market share.

The rapid rise in prices has made it risky for traders to ship down stockpiles, as the delivery process takes about two months, creating uncertainty over future market conditions. A trader based in Europe remarked, “this situation is causing a very low unsold inventory level internationally, keeping the price for prompt material at a very high level.”

As the market grapples with this unprecedented spike in prices, the Wuxi Stainless Steel Exchange's most actively traded bismuth contract showed a transaction price of 163,800 yuan, equivalent to $22,677 per metric ton, marking a 105% increase since the beginning of the year.

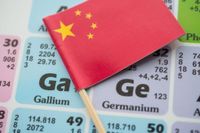

In addition to bismuth, China has also enacted strict export controls on germanium and gallium, crucial metals used in semiconductor manufacturing and high-end applications. Since the July 2023 measures, which necessitated government permission for exports, there has been a notable decline in exports of germanium and gallium from China, especially affecting the United States and its allied nations focusing on chip manufacturing.

Chinese officials report zero exports of these metals to the United States in 2024, yet discrepancies in U.S. trade data indicate that some germanium and gallium imports may still be trickling in through third countries like Belgium. This duality presents a complicated picture particularly as China announced a comprehensive ban on exports of these metals to the U.S. in December 2024.

Amid these restrictions, the USGS predicts a potential spike in prices—anticipating a 150% increase for gallium and a 26% rise for germanium. The financial implications are staggering, with estimates suggesting that broad restrictions may lead to a $3.4 billion drop in the U.S. GDP.

This underscores the fragile dynamics within the global supply chain for these critical minerals and highlights China's crucial role as a global supplier.

The overall landscape regarding germanium and gallium presents a broader narrative of where American reliance on foreign minerals stands amid growing geopolitical tensions. With U.S. consumption levels remaining stable yet importing less—68% less germanium and 77% less gallium from 2021 to 2024—many industry observers are left to wonder: how will the U.S. adapt to these emerging realities?

As domestic recycling and processing capabilities ramp up to offset some impacts, uncertainty looms over the sustainability of these efforts, particularly for gallium, given that the U.S. does not maintain an adequate stockpile. Meanwhile, pressures mount for U.S. companies to increase production capacity in response to shifting supply chains influenced by China’s export policies.

In this context, the repercussions of these developments extend beyond fluctuations in prices. They pose challenges to U.S. manufacturers reliant on these materials and point to a necessity for strategic planning to cope with the evolving global markets. China’s grip over critical mineral supplies remains an influential factor as the U.S. navigates through these complexities well into the future.