The mining industry is undergoing a transformation towards sustainability, and a recent study showcases an innovative approach to enhance the properties of cemented paste backfill (CPB) using basalt fiber (BF). This study, published on March 24, 2025, examines the impact of BF on the mechanical, rheological, and thermal properties of CPB, crucial for improving mining practices.

Incorporating BF into CPB presents a promising solution to reduce binder content and enhance stability during ore extraction. The study conducted by M.A. Hefni involved adding two lengths of BF—12 mm and 18 mm—at varying dosages (0.50%, 0.75%, and 1.0%) to CPB mixtures composed of tailings from a Canadian mine. This method not only aims to find sustainable materials but also to improve operational efficiency in underground mining.

The findings revealed that adding 18 mm BF at a dosage of 1% significantly decreased the slump value by up to 74% compared to control samples, leading to increased yield stress from 191.8 Pa to 398.8 Pa. This reduction in slump indicates enhanced cohesiveness within the CPB, allowing for better placement and less segregation during mining operations.

Additionally, incorporating 12 mm BF at a 1% dosage improved the uniaxial compressive strength (UCS) of the CPB by an impressive 35% after just 7 days of curing. This enhancement signifies that CPB can achieve higher strength levels, which is essential for maintaining stability in underground environments.

The study also highlighted a crucial thermal advantage; the thermal conductivity of CPB reinforced with 12 mm BFs at a 0.50% dosage decreased by nearly 36%. Such a reduction can lead to improved temperature regulation underground, crucial for ensuring operational safety and efficiency.

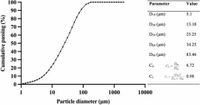

Ordinary Portland cement (OPC) was used as the binding agent in the mixtures, which featured a specific gravity of 3.15, while the tailings derived from the Canadian mining operation had a specific gravity of 2.74. The CPB mixtures were prepared with a binder dosage of 5% and a pulp density of 72%, cured at temperatures of 20 ± 2 °C and relative humidity of 90 ± 2% for periods of 7, 14, and 28 days.

In terms of workability, the slump significantly decreased across all BF dosages, directly correlating to an increase in yield stress. This aligns with the study’s claim that longer fibers and higher dosages create a more viscous mixture, enhancing the CPB structure. The researchers stated, "The addition of 18 mm BF to the CPB at a dosage of 1% decreased the slump value by up to 74% compared with the control." This illustrates the pivotal role BF plays in enhancing the physical properties of CPB.

Moreover, the ultrasonic pulse velocity (UPV) tests indicated that for all samples, UPV increased with curing time, confirming successful binder hydration effects. However, the presence and quantity of BF exhibited complex interactions that required careful optimization. The UCS results followed a similar trend, where the addition of BF improved strength during earlier curing stages, although by day 28, UCS levels between BF-reinforced and control samples converged.

This engaging research suggests that while basalt fiber significantly enhances backfill properties, optimal dosages and fiber lengths are essential for maximizing their effects. The thermal efficiency brought about by reduced thermal conductivity can mitigate energy costs in underground mining, making these findings relevant in a sector facing growing environmental scrutiny.

As mining operations seek to incorporate more sustainable practices, utilizing BFs could represent a strategic shift in the industry, enhancing not only the economic feasibility but also the safety and environmental impact of mining activities. The authors concluded that with ongoing research, the potential of BF in reinforcing CPB can lead to innovative solutions that improve the safety and stability of mining operations.

Future studies are anticipated to explore variations in tailings characteristics and BF interactions further, as well as applications in field trials to validate laboratory results. Only by comprehending how these materials behave under operational conditions can the mining industry enhance its environmental footprint and operational success.