A New Machine Learning Model Significantly Improves Gas Holdup Predictions in Airlift Reactors

Innovative techniques enhance the design efficiency across chemical and bioprocessing applications

In a ground-breaking study, researchers have significantly improved the accuracy of predicting gas holdup in Internal Loop Airlift Contactors (ILACs) using advanced machine learning techniques. This development not only promises to enhance reactor design efficiency but also has important implications for various chemical and bioprocessing industries.

The study, published on March 20, 2025, consolidates data from 324 points sourced from previous experimental studies on ILACs to create a robust model aimed at addressing the significant challenges faced with existing empirical models that often fail to deliver under varying operational conditions. The research is spearheaded by H.P. Prabhu, C.M. Ravishankar, and their colleagues, who sought to utilize machine learning to refine the predictive accuracy of gas holdup, an essential parameter affecting the performance of multiphase reactors.

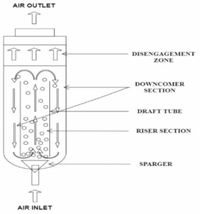

ILACs, modified from conventional bubble columns, are employed in various applications such as wastewater treatment and microalgae cultivation. The accurate prediction of gas holdup is crucial in designing these reactors, as it impacts liquid circulation velocity, mixing behavior, and ultimately the efficiency of the processes involved. Previous correlations predicting gas holdup in ILACs often relied on limited parameters, undermining their applicability in real-world scenarios.

To tackle this issue, the research team employed a Random Forest (RF) regression model optimized through Genetic Algorithms (GA). This data-driven approach allows for the handling of multiple operating parameters and captures nonlinear correlations among them—the complexity that simpler empirical models fail to address. The algorithm achieved an impressive Coefficient of Determination (R²) score of 0.9542 and Mean Absolute Error (MAE) of 0.0059, showcasing a substantial improvement in predictive accuracy.

The dataset used in this study incorporates ten essential features, including superficial gas velocity, draft tube diameter, viscosity of gas and liquid, and others, which collectively impact mass transfer efficiency and flow circulation within the reactor. The application of machine learning techniques, specifically RF regression enhanced through hyperparameter tuning, demonstrates a marked improvement over conventional modeling methods.

“The tuned model achieved a Coefficient of Determination (R²) score of 0.9542 and Mean Absolute Error (MAE) 0.0059, surpassing traditional parameter sets and providing insights into hydrodynamic control,” wrote the authors of the article. This marks a significant advancement in the field, as predictive models in this area have historically relied on empirical correlations that can overlook critical interactions among multiple factors.

Furthermore, the research leverages SHapley Additive exPlanations (SHAP) to interpret predictions, offering valuable insights into the contribution of various features impacting gas holdup. This methodology enhances model transparency and allows researchers to understand better how each parameter influences predictions, a crucial aspect for optimizing reactor design.

“This study demonstrates the efficacy of RF regression optimized by GA for predicting gas holdup in ILACs, achieving an R² of 0.9542,” the authors noted. Such advancements not only facilitate the design of more efficient airlift contactors but can also lead to cost-effective applications in industrial processes like wastewater management and bioenergy production.

In conclusion, the findings underscore the promise of utilizing machine learning, particularly RF models, in enhancing the design and operational parameters of multiphase reactors. The integration of advanced statistical methods, such as SHAP, opens new avenues for innovation in reactor design processes, leading to more sustainable and efficient technologies. Future research could expand datasets to include varied industrial-scale contexts, thus broadening the applicability and reliability of these predictive models.